Clear explanations.

Master difficult engineering subjects with clear, intuitive explanations.

Built by engineers with real world, industry experience. Learn the fundamentals the way they should have been taught.

Master difficult engineering subjects with clear, intuitive explanations.

The only way to achieve A level grades is through practice. Our courses contain hundreds of relevant, exam style problems.

Our Scandinavian instructors combine cutting edge technologies to give you the best learning environments.

The complete and full course bundle including all the courses in the Thermodynamics Exam-Prep Series and more!

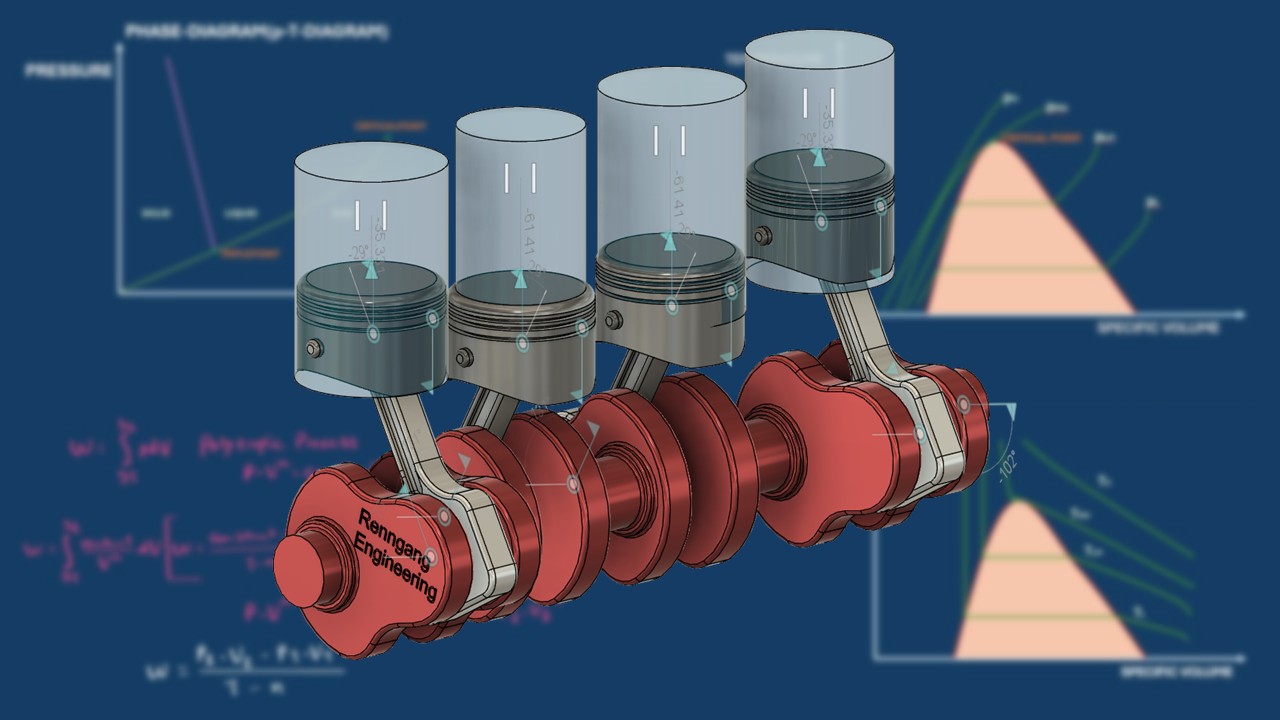

Exam-focused fundamentals, tables, diagrams, and problemsolving methods for engineering students.

Energy balance, Heat, work, COP, and exam style problem solving to help you ace your exams.

Entropy explained clearly with balance equations and exam style examples.

Energy balance, heat, work, COP, and exam style problem solving to help you ace your exams.

Exam-focused fundamentals, tables, diagrams, and problemsolving methods for engineering students.

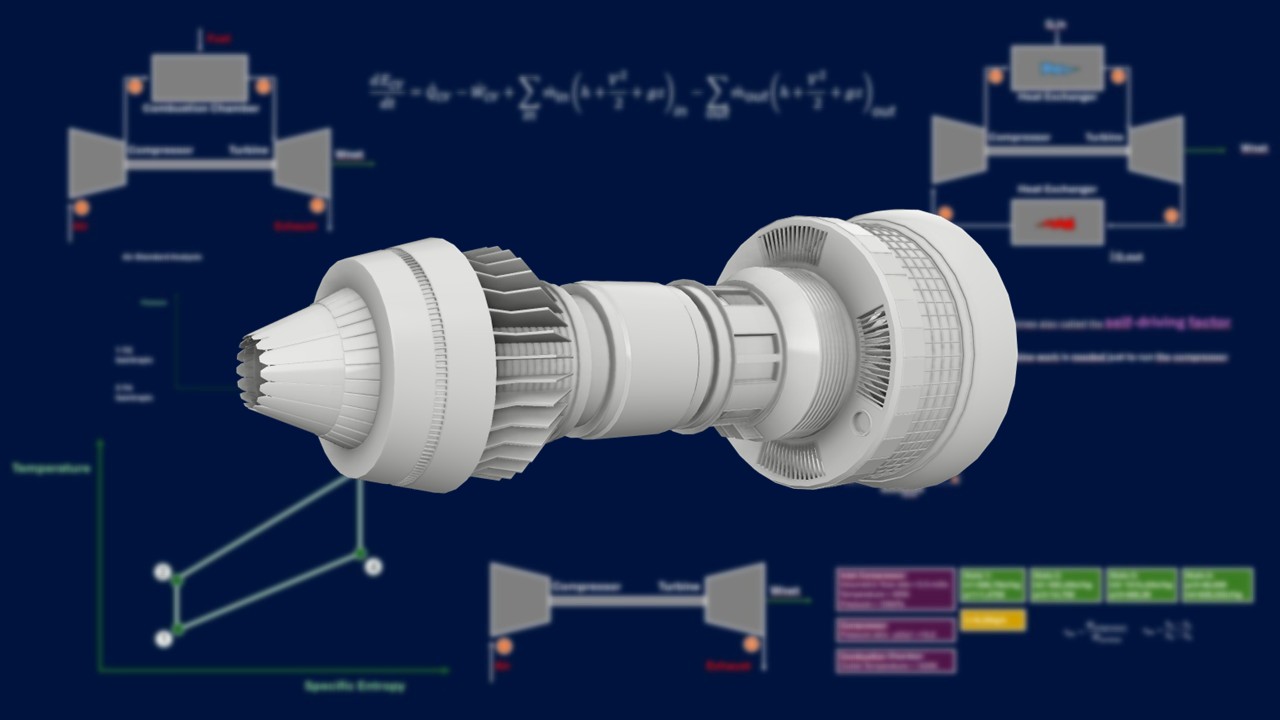

Rankine, Brayton, Heat Pumps, Components, and Exam style Problem Solving